Shangqiu Hengchuang Environmental Technology Co. LTD the company latest full continuous low temperature rubber pyrolysis machine can increase oil output, reduce fuel consumption ensure no burns and explode during operation. Detailed introduction of HCL- series continuous low temperature rubber pyrolysis machine goes as follows:

1):Labor saving investment :Automatic continuous pyrolysis equipment by using integrated control is more simple,effectiveness . The feeding, carbon black discharge , cracking, etc are all speed adjustable . One person can achieve the full operation 。

Equipment using fuel oil/gas/electricity/and cracking of oil gas again after their purification system of processing to achieve no pollution emissions standards.

2):Big treatment capacity :Due to realize the continuous feed, continuous slag discharge , continuous process , so the daily capacity is larger than ordinary batch cracking equipment.

3):Low energy consumption:After normal production the pyrolysis oil gas itself heat is enough to use, therefore, it greatly reduce the fuel cost and almost no longer add additional heating fuel. Equipment overall heat preservation effect is good, less heat, electricity power stable low energy consumption.

4):Equipment operation stability:This equipment reactor due to use car sales way of finishing processing is high precision, beating minimal operation, at the same time, adopt more tug pivot support, overall runtime without beating and vibration .So that it is more stable than ordinary batch cracking machine . Completely solve the users concern about the equipment run time is not stable

5)Machine longer life time :

Comprehensive equipment running smoothly, strict temperature control and realize the low temperature cracking, minor negative pressure production, and many other advanced ideas, to make the equipment can run over a long period of time .

The system using the liquid crystal display (LCD), industrial computer remote control operation, is a precise control operating system of the collection of concise and straightforward, monitoring operation, efficient operation,

The pollution-free, green environmental protection, improve the productivity, reduce the non-renewable energy consumption, and effectively strengthen the production safety of the users . Approach to realize the low temperature, constant temperature cracking of black garbage, so as to get fuel oil.

This device heating source get rid of the traditional industrial coal heating mode, now the main heating fuel is natural gas , fuel oil and the waste gas itself collected .

Combined with the hot air circulation principle,, improved the utilization ratio of resources greatly.

2 :Raw materials and machine function .

1: Machine function : This machine mainly used to process and crack the rubber granule .The end product is fuel oil , carbon black and less small steel .

2: Raw materials shall be clean, not too much dirt, dust and so on, otherwise it will have influence on fuel oil quality .Materials Water content can't be too high, if too high it impact equipment cracking speed and efficiency . General requirements is no water damage.

3: The early stage of the raw materials need to be broken processing, material shall be rubber granule shape, no steel and other impurity. The picture as follow:

The end product from the rubber granule pyrolysis machine :

|

NO

|

Name

|

Raw material : rubber granule

|

|

Output

|

Usage

|

|

1

|

Fuel oil

|

35%-50%

|

*Use for the fuel factory, such as the glass factory , ceramic factory ,boiler factory and so on.

|

|

2

|

Carbon black

|

42%- 50%

|

* Use the carbon black refining machine to process.

|

|

3

|

Waste gas

|

8%-14%

|

*80% is recycled as fuel to heat machine itself directly .

* The 20% rest gas is collected by waste gas collection system.

|

|

4

|

Steel wire

|

0.005%

|

*Recycled to steel factory.

|

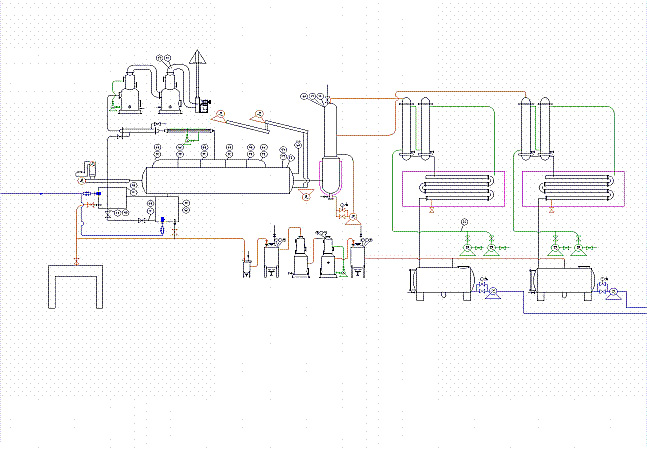

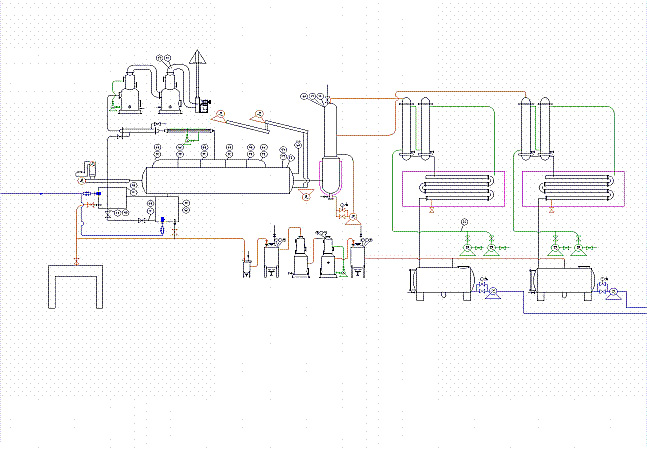

3 .HC-2436 model continuous pyrolysis machine flow chart and working principle go as follow :